Do you ever wonder about the utilities in a building that you can’t see? Those that are hidden behind walls, the ceiling, and the floor.

Well, most of the utilities are usually installed once the framing of the building has been completed. This is what we call rough-in, in the construction industry.

The work is not limited to a single trade, there are many rough trades in construction.

Think of the rough-in as the foundation for the functionality of the building. Many steps come following this phase of construction. Rough-in needs to be done before any finishes are installed.

Once the end fixtures are installed you can make the connections to the material installed during rough-in.

In this article, we will look at the rough-in process and the trades involved. I will share some pictures that I took while on a job site so you can identify rough-in work.

The Meaning of Rough Trades in Construction

There is no single “rough trade” in construction. Most trades have a portion of rough-in work that needs to be done for a project. The work involves installing your electrical conduit & wiring, piping (gas, water, refrigerant), and HVAC ducting.

These members of a construction project are vital to providing a building with functionality. This applies to both new construction and renovation projects.

You should also note that this is done before any of the end fixtures are installed.

For electricians, this is your electrical outlets, electrical fixtures, and tie-in to large equipment.

Plumbers will be involved with hot water systems, toilets, faucets, etc…

Pipefitters and sheet metal workers will be your connections to HVAC systems like a fan coil unit for air conditioning.

Here are Some Examples of Rough-in Work at a Construction Site

Electrical Rough-in Work

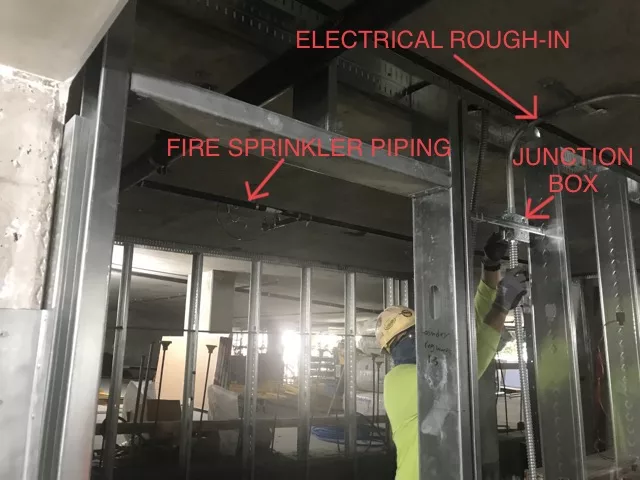

The first image is right after the metal studs of the wall were installed. It allowed for the rough-in to begin.

In the image, the electrician is working at the junction box. Junction boxes are used to make the wire-pulling process smoother.

In the image, the electrician is working at the junction box. Junction boxes are used to make the wire-pulling process smoother.

The next image involves a project that I worked on where we had to install a generator. The electrician needed to rough in all the underground conduits for the new electrical system.

Once the rough-in was complete, we were able to pour a concrete jacket, backfill and create new equipment pads.

Once the rough-in was complete, we were able to pour a concrete jacket, backfill and create new equipment pads.

Don’t Forget Your Low Voltage Electrician

You’ll be able to see a few different trades in the next photo. At this point of the project, the rough-in was complete and the general contractor began installing the interior walls.

There’s a mix of power conduit, flex conduit for your low voltage wires, fire sprinkler & plumbing lines, and data cables in this photo.

There’s a mix of power conduit, flex conduit for your low voltage wires, fire sprinkler & plumbing lines, and data cables in this photo.

Notice how the flexible conduit is coiled up in a long bundle. Since you don’t make the final connections during rough-in, you need to reserve enough material to make the connection.

HVAC Contractor Rough-in Work

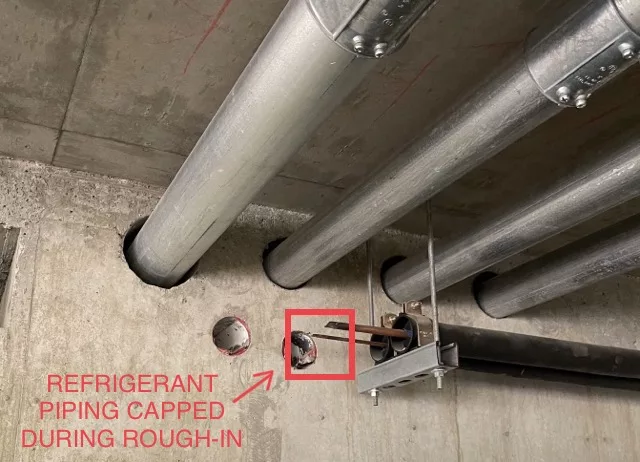

The following image displays the refrigerant piping rough-in process. You have refrigerant that flows from an outdoor to an indoor AC unit to provide cooling.

During the rough-in, the pipe fitters will cap the ends of the pipes. By doing this, they prevent contaminants from entering the pipes during the construction process.

During the rough-in, the pipe fitters will cap the ends of the pipes. By doing this, they prevent contaminants from entering the pipes during the construction process.

Next, we will look at the sheet metal side. In the photo below, it’s a bit difficult to tell but the ductwork rough-in has been completed.

The air handling unit has just been set and is ready for the final connections.

The air handling unit has just been set and is ready for the final connections.

Your ductwork openings are covered with blue plastic material to prevent dust and debris from entering.

The sheet metal worker can now rough in the remaining ductwork and install a flex connection to the AHU.

Also, don’t forget about the piping. This equipment requires cold-water pipes to be connected to provide cooling.

Your pipe fitters will need to return to the job site and make their connection to the equipment as well.

Here’s a Video Inside a Construction Site Following the Rough-in Phase

The video below is following the rough-in stage of construction, and right after the rough-in inspection. The building inspector came in and passed the work allowing the general contractor to begin the finish work.

I find this video interesting because you can see the sheer amount of piping, ductwork, and electrical wiring in the ceiling.

That’s why I appreciate construction work. The amount of coordination required to make everything fit with the space constraints is amazing to me.

How Many Rough Trades are There in Construction?

There are various trades are involved with rough-in, each have their own line of specialty work. As a trade worker you have many different paths to branch off into.

Trades that have a place during the rough-in process are as follows:

- Electricians: Will typically run either conduit or wiring for…

- Low voltage controls for HVAC work

- Fire alarm systems

- Lighting

- Power or Electrical panel

- Pipefitters: Will install piping for…

- Chilled water piping

- Refrigerant piping

- Sheet metal workers: Will install ductwork for…

- HVAC ductwork

- Plumbers: Will run piping for…

- Domestic water supply

- Sewage

- Storm drain

- Fire sprinkler

- Gas lines

- Hot water heater

If any rough-in is missed, and you close up the walls you’ll have to take them back down. This will result in some unhappy workers if they have to do something twice.

So, it’s important that confirm everyone has completed their rough-in before you proceed with the finish phase.

Note: When I mention, “close up the walls” I am referring to the process of mounting drywall to the frame. When a building has just metal or wooden framing it’s considered open and is ideal for rough-in to begin.

Rough Carpentry in Construction

I wanted to mention this trade because their work is called “rough carpentry”. Their work is a bit different than the trades mentioned above.

With rough carpentry, they will install most of the rough framing for a new home or building.

This can consist of the following items:

- Wooden studs

- Roof rafters

- Ceiling joists

- Floor joists

The work for rough carpenters has its own phase in a project. It needs to be completed before mechanical work, electrical cables, or plumbing rough-in can begin.

When Does Rough-In Occur on a Construction Project?

As you already know, rough-in can begin once the framing is completed for a project.

But this doesn’t happen all at once. You need to phase the work so that the trades don’t interfere with one another.

You need to consider which trades will be the most impacted by other utilities.

If you’re working on a project that has HVAC ducts, you will likely want these guys to go first. Their work will take up the most space and clearance is critical for this trade. Improper installation of the ductwork can impact the performance of your HVAC equipment.

Once sheet metal is done, you can bring in the pipe fitters and plumbers, followed by the electricians.

The reason you have electrical come in last is that their work is the most flexible. Their conduit or wires are much smaller in comparison. We’re talking about one 1/2 to 1-inch piping used to house their wiring.

There’s a caveat to this, any large power distribution system will require a larger conduit. This is any conduit that’s greater than 4 inches.

When dealing with metal conduits greater than 4 inches, it can be difficult to install since you can’t bend them yourself. If this is the case, you might need to bring in your electricians earlier in this stage of the rough-in process.

During rough-in you need to consider any potential accessibility issues. Any material installed that prevents access to your equipment will be a problem for maintenance.

What Happens After Rough-in is Completed?

Now that the rough-in is completed on your project, you will need to get all that work inspected. By doing this you implement some level of quality control for the project.

The inspection will be completed by your local building department. They will send out the authority having jurisdiction (AHJ) to perform the inspection.

Your AHJ will come to the job site to look at the work completed. They will inspect the work to confirm that it follows building codes.

I should note that the contractor responsible for the actual work should be calling for these inspections.

Before you can even request an inspection, you need to make sure the building permit has been obtained.

When the permit is issued, you should be provided with the phone number to call for inspections. Distribute these numbers to the appropriate team members.

It’s important to know that inspectors can make your life hell if you don’t install per code. If they tell you to fix something, you do it.

Even though it’s extra work, you can’t finish a project if the inspector does not give his blessing.

Once you’ve made the required corrections, you call for a final inspection so the AHJ can pass your work.

Note: Inspectors will use their best interpretation of the code. They will not always be right about the code. It’s ok to question something should the inspector falsely impose something on you.

Quick Story with Building Inspectors

I mention this note because I was involved in a situation where the inspector misinterpreted the code. He wanted us to get all our control panels UL listed.

This would’ve cost the company over $50,000 to certify 200+ control panels.

We carefully reviewed the code they were referencing and provided our interpretation. After some back and forth, they ended up dropping the requirement.

What a stress relief that was!

It just goes to show that they’re not perfect, but will do their best to make sure the work is done properly.

Work Following the Inspection

Rough-in is completed and your inspections all check out. You can now begin closing the walls and ceilings for your project.

You are now one step closer to completing the project!

Key Takeaways

As project managers, you should be familiar with the different phases of a construction project.

Rough-in is just one portion of a project but it’s so critical to get this right. Know when this work fits into the job for scheduling and coordination help.

Being able to identify rough-in work between the trades will be beneficial to you on your next construction project.

If you understand the different trades work, you can determine how far along they are. This is valuable information for phasing the work or scheduling the next subcontractor.

Before you go, I suggest checking out my article on pre-task planning. This will take you through the steps on how construction workers plan for a new activity like rough-in.

Thank you for reading.

Table of Contents